|

|

|

ASTATIC: An Idea that grew

into an Industry

NOTE: This history was

taken from an Astatic brochure from circa 1946.

F.H. Woodworth, President |

|

C.M. Chorpening, Vice President |

Away back

in 1930, two radio amateurs, C.M. Chorpening, W8WR radio

(now W8MJM), and F.H. Woodworth, W8AHW, both of Youngstown, Ohio, began

searching for a better microphone for their 'phone transmitters. Up until this

time they had been using various carbon type microphones. The condenser type

appealed to them as an answer to their problem. Several units were designed and given trials

on the air. Before long, other amateurs among their

acquaintances began visiting their shacks, interested in either

building or buying this new type of "mike." Chorpening and Woodworth,

encouraged by this

interest, decided to form a partnership and build these units for their friends.

While this condenser unit proved reasonably satisfactory, it had certain

limitations which it was hoped could eventually be overcome.

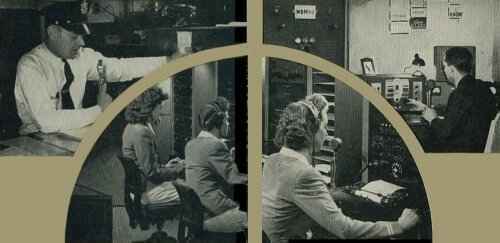

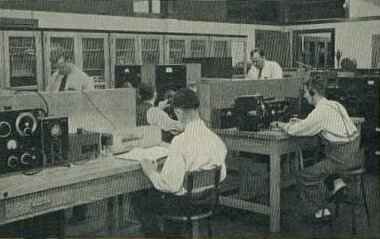

A group of Astatic officials and employees in the early days. |

NEW ELEMENT SUGGESTED

It was about this time that an old acquaintance, Mr.

Charles E. Semple, of Cleveland, who had been visiting his "ham" friends

frequently, invited them to pay him a visit.

With a background of phonograph and loud speaker experience, Mr. Semple

was then occupying bench space in the Brush Laboratories, experimenting with elements made from Rochelle Salts,

(Sodium Potassium Tartrate). Through Mr. Semple, the

two visitors met A.L. Williams, electrical and mechanical engineer, and Dr. C.B.

Sawyer, scientist, who demonstrated to them the action of these new elements in relation

to microphones, phonograph pickups, speakers, recording heads,

earphones, and other devices where it was desired to transform mechanical

energy into electrical energy or the reverse. Here, it seemed, they had found

the answer to a simple, low cost, dependable

"mike" for the ham rig.

Astatic's first Crystal Microphone, Model D-104. Manufactured in 1933. |

Humble home in which Astatic had its beginning. |

INCORPORATED IN 1933

By 1933, Messrs. Chorpening and Woodworth found it advisable to

incorporate a manufacturing and sales company and to branch out with a line of Crystal

Microphones, Crystal Phonograph Pickups and Recording Heads for manufacturers

and radio jobbers. Mr. Semple was brought into the new organization as designer,

and later served as general manager until his death in 1939.

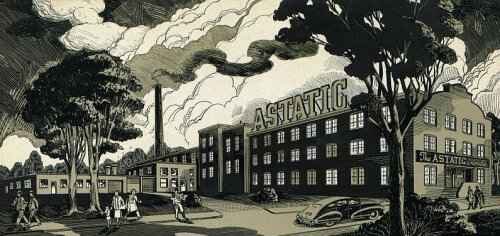

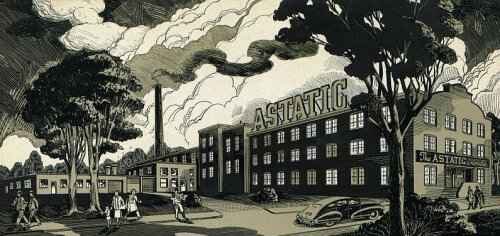

Main Plant and

Offices of The Astatic Corporation at Conneaut, Ohio |

Today, The Astatic Corporation occupies a large, modernly equipped plant on a

three-acre tract of ground in the heart of Conneaut, Ohio, second largest

ore-unloading port on the Great Lakes. The move to Conneaut, from

Youngstown, Ohio, where Astatic was originally incorporated and maintained its

offices and manufacturing plant until late in 1944, was made necessary by the

rapid growth of this important electronics parts industry. Like every new

manufacturing venture, Astatic experienced, but successfully overcame, many

vexing problems to finally find a place of leadership in an industry which today

knows scarcely any limitations. A pioneer in this relatively new field of

science, Astatic has contributed immeasurably to the fidelity of sound pickup

and reproduction as related to radio, electric phonographs and combinations,

with their multiplicity of applications. As the use of electronic devices became

more generally understood and practiced, the demand for Astatic Microphones,

Phonograph Pickups and Cartridges increased and Astatic moved forward in product

design and product facilities.

Left to right: assembling needle chuck to crystal element; servicing

microphone cables; testing phonograph pickups |

The phenomenal growth of The Astatic Corporation is best illustrated by the fact

that twelve hundred employees, as compared to less than a dozen during the first

year of Astatic annals, are now engaged in the manufacture of Astatic's large

line of products. The name "Astatic" has become a symbol for Microphones and

Phonograph Pickups, familiar to everyone interested in electronics. With

representatives in eighteen key American cities, as well as in foreign

countries, the market for Astatic products is world-wide.

General View

of Main Assembly Floor |

A trip through Astatic's modern Conneaut plant and its amazing complicity of

operations is a revelation in manufacturing achievement. Machines and equipment

of the most modern design are utilized for the making of tools and dies,

machining of parts, in assembly operations, finishing and otherwise contributing

to the manufacture of Astatic products. Visitors to this Astatic plant are

deeply impressed with its modern equipment and facilities, with its fully

equipped laboratory and large engineering department, with its extensive tool

and machine shops, its up-to-the-minute painting and drying department, its

long, busy lines of assembly workers, large office personnel, its clinic, its

cafeteria and other features. And one cannot fail to be impressed, as well, with

the constant supervision over all these operations, designed to insure, through

careful manufacture and constant testing, the ultimate performance of Astatic

products in the field.

Assembling Pickup Cartridges |

Left to right:

Testing Astatic microphones, testing crystal cartridges, cementing

damping pads in cartridge housings |

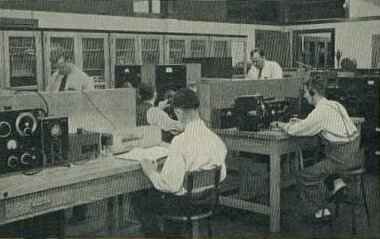

Astatic engineering personnel,

quarters and equipment have been extensively increased at the new Conneaut plant

to facilitate research and development work. This new department now includes a

modernly equipped laboratory with the most approved types of measuring and

testing equipment, and is co-ordinated with the

mechanical engineering and drafting units.

Partial view of Astatic Engineering Laboratory |

FIELD OF APPLICATIONS FOR ASTATIC PRODUCTS IS CONSTANTLY INCREASING

With science delving ever deeper into the possibilities of electronics, the

broadening field of applications for Astatic pickups and sound reproducing

devices knows scarcely any limitations. Long familiar to almost everyone

associated with radio and phonograph manufacturing and amateur activities,

Astatic Microphones, Phonograph Pickups, Cartridges and Recording Heads are now

destined to find modern uses in hundreds of new applications. Astatic engineers

and laboratory technicians are in a position to offer assistance to Astatic

customers in the possible adaptation of Astatic products to special

applications.

Mobile Sound

System equipped with two Astatic K-2 Microphones |

Astatic Crystal and Dynamic Microphones are designed in many models for general

use, as well as special applications. Among these are: radio broadcast stations;

amateur radio stations; public and mobile address systems; airway

communications; police radio networks; inter-office, plant, and field

communications systems; educational institutions; home recording combinations;

office dictating machines; criminal detection devices and many others. Their use

now, naturally, will include two-way communications systems for railroads,

ships, bus lines, taxicab networks. In addition, Astatic Microphones have many

and varied industrial applications; to test machinery for vibrations and noises;

watch timing; water-leak detection and location; and other special demands.

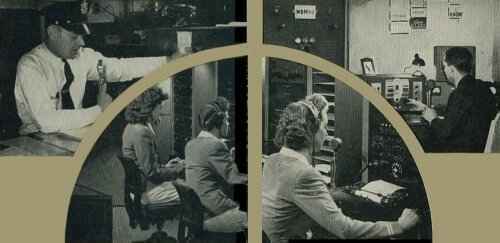

(upper left) Police Network Installation employing Astatic

Microphones.

(center left) Astatic Microphones used in Airline Dispatch.

(center right) Office Installation with Wilcox Elec. Co. equipment.

(upper right) Astatic Microphones extensively used with amateur rigs. |

Astatic Phonograph Pickups and

Cartridges are used by a majority of the leading manufacturers of electric

phonographs, radio-phonograph combinations, coin operated phonographs, home

recording combinations, and other similar types of equipment. Most phonograph

pickup arm designs used by important set manufacturers are based upon Astatic

Cartridge dimensions, thus making Astatic Cartridges suitable for practically

all replacement requirements.

Two versions of Astatic Pickup Arms as used on portable phonographs. |

In addition to supplying

manufacturers of original equipment, Astatic products are distributed by parts

jobbers here and abroad for repair, replacement and improvement of existing

equipment.

Phonograph Pickup Cartridges, of

which Astatic is perhaps the world's largest producer, are made in many models

to meet today's varied requirements and exacting demands. It is natural,

therefore, that Astatic Cartridges are the choice of most engineers designing

phonograph equipment, whether it is for simple, manually operated players or the

most elaborate automatic changer combinations.

Manufacturer

and Jobber Service Department |

For the accommodation of its many

Radio Parts Jobber and Manufacturer customers, Astatic has long maintained a

special service department. Products failing to meet Astatic's high standards of

operating efficiency, as the possible result of defects in material or

workmanship, are here repaired or replaced according to their needs. This

cooperation insures customer satisfaction and confidence.

Astatic Microphones popular for public address and sound system

applications. Tommy Tucker's Orchestra shown above using Astatic

microphones. |

ASTATIC'S CONTRIBUTION TO THE WAR

EFFORT (WORLD WAR II)

For its liberal contribution to the

war effort, The Astatic Corporation received, along with many congratulatory

letters for meritorious accomplishments, the U.S. Navy Certificate of

Achievement.

In addition to great quantities of

Microphones, Pickups and Crystal Cartridges supplied to the Armed Forces and

essential industries during the war period, Astatic designed, perfected and

manufactured many other types of electronic equipment. Included were a number of

under-water sound detection or Sonar devices. Astatic, as a result, became one

of the largest producers of Hydrophones for the U.S. Navy under direct contract,

and for other manufacturers of Sonar equipment on a subcontract basis.

For Army and Navy Bomber and

Fighter Planes, Astatic perfected and produced, in large quantity, a Static

Discharger, for dissipating static electricity which accumulated, due to

friction in flight, on wing surfaces, fuselage and tail assemblies.

A further contribution was made by

Astatic in the design and manufacture of Co-Axial Cable Connectors used

exclusively by both the Army and Navy for Radio, Radar and Sonar hookups and

installations. As a result, The Astatic Corporation became the country's largest

producer of these items, shipping in one month, during peak production, a total

of over 650,000 units. |